سبد خرید شما خالی است.

گوگرد جامد توده ای را می توان با استفاده از روش های مختلفی از جمله تخته سنگ، دانه بندی، دانه بندی هوا و مرطوب و پاستیلاسیون تشکیل و تولید ...

Bulk solid sulfur can be formed and produced using different methods such as slate, granulation, air and wet granulation, and pastillation. Granulation and pastillation are two very common methods for producing bulk solid sulfur.

Granulation or pastillation as a method for producing bulk solid sulfur is often found in facilities where raw elemental sulfur is processed into a final or intermediate product, or in facilities (such as oil refineries) where sulfur is a by-product of another product. It is recycled. Production Process. In both processes, bulk material handling equipment plays a vital role in transporting sulfur granules and produced pellets.

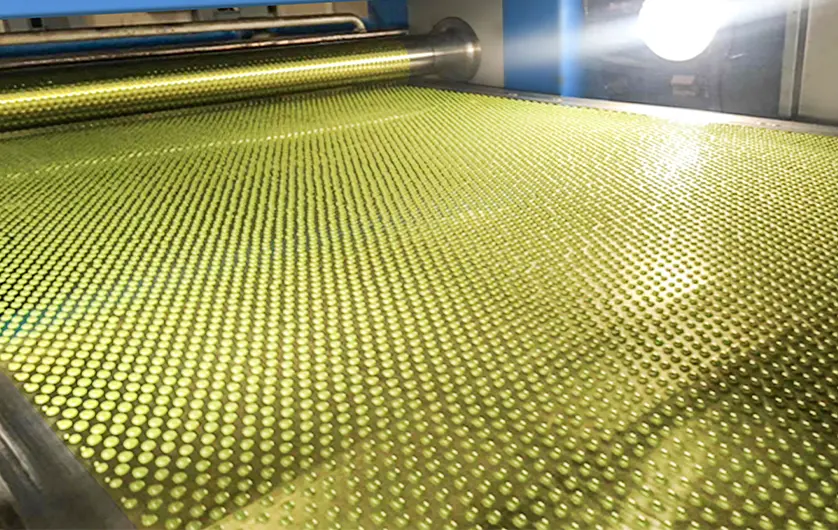

In sulfur pastillation, liquid sulfur droplets are placed in regular rows on the cooling steel belt using a liquid sulfur injection device. Liquid sulfur loses heat by moving on the steel belt cooler and becomes a uniform hemispherical shape called pastille.

The formation of sulfur pastilles is a growing method for the production of solid sulfur due to the relative ease of installation and the high quality of the final product. Another advantage of pastille is its versatility. The same equipment can be used to produce other products such as sulfur bentonite and urea.

Irfan Sanat Bastan Company is proud to announce that it has the ability to manufacture and produce all the devices and equipment needed for pastel sulfur production units.